A few years ago, the role of IoT in traditional sectors like manufacturing was anything but well-defined. But today, connected equipment and solutions are redefining factory operations and supply chain management. And not just IoT solutions, a plethora of technologies digitally transforming the industry at a dizzying pace. What are the most potent factors driving these evolution’s? Experts say consumer behavior and shifting market dynamics are the most crucial ones.

Manufacturing companies are increasingly resorting to IoT development services for process digitization. By deploying IoT solutions, businesses have gained unprecedented productivity and uncovered new means of improving d supply chains.

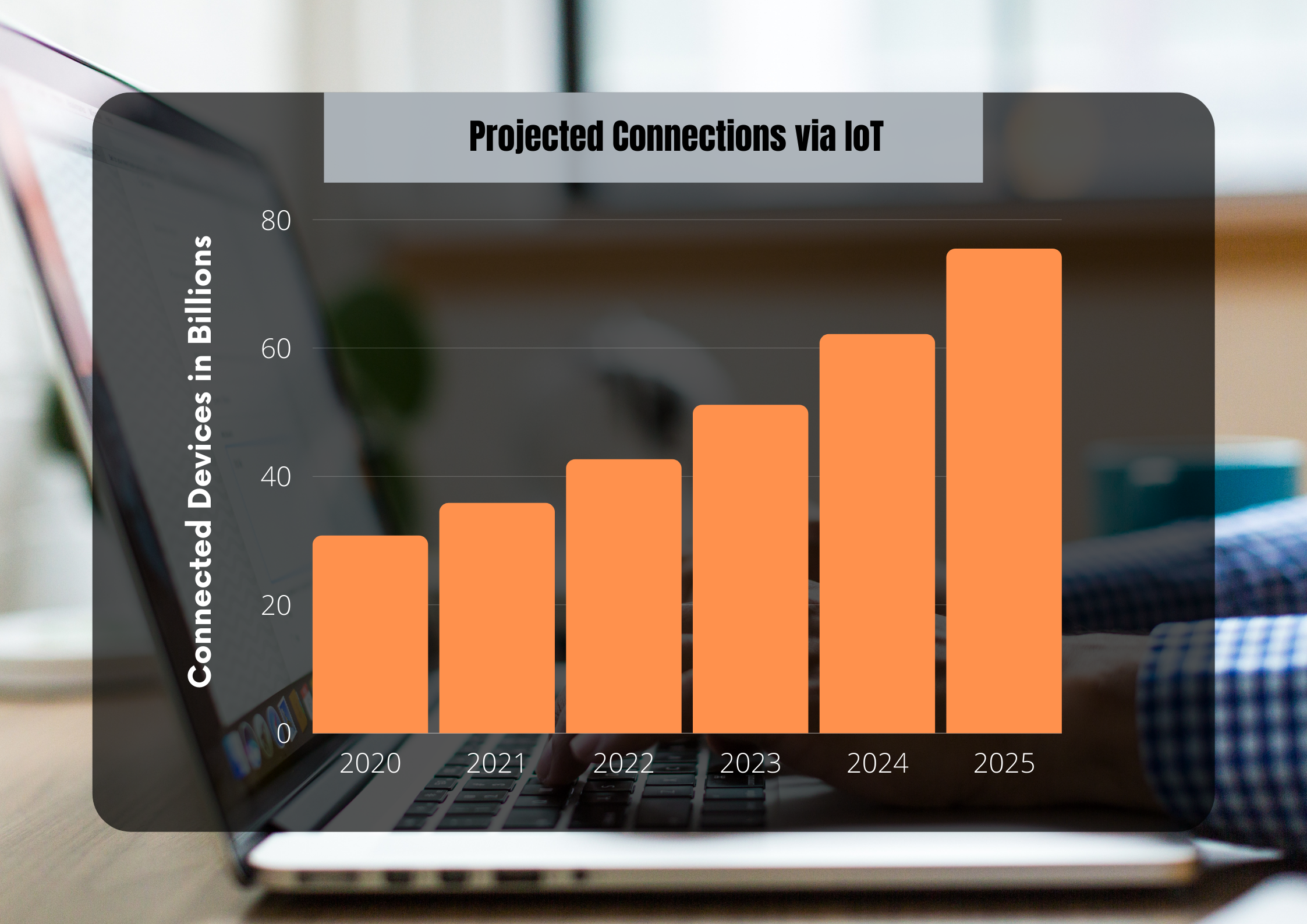

Industrial Applications of IoT in Numbers

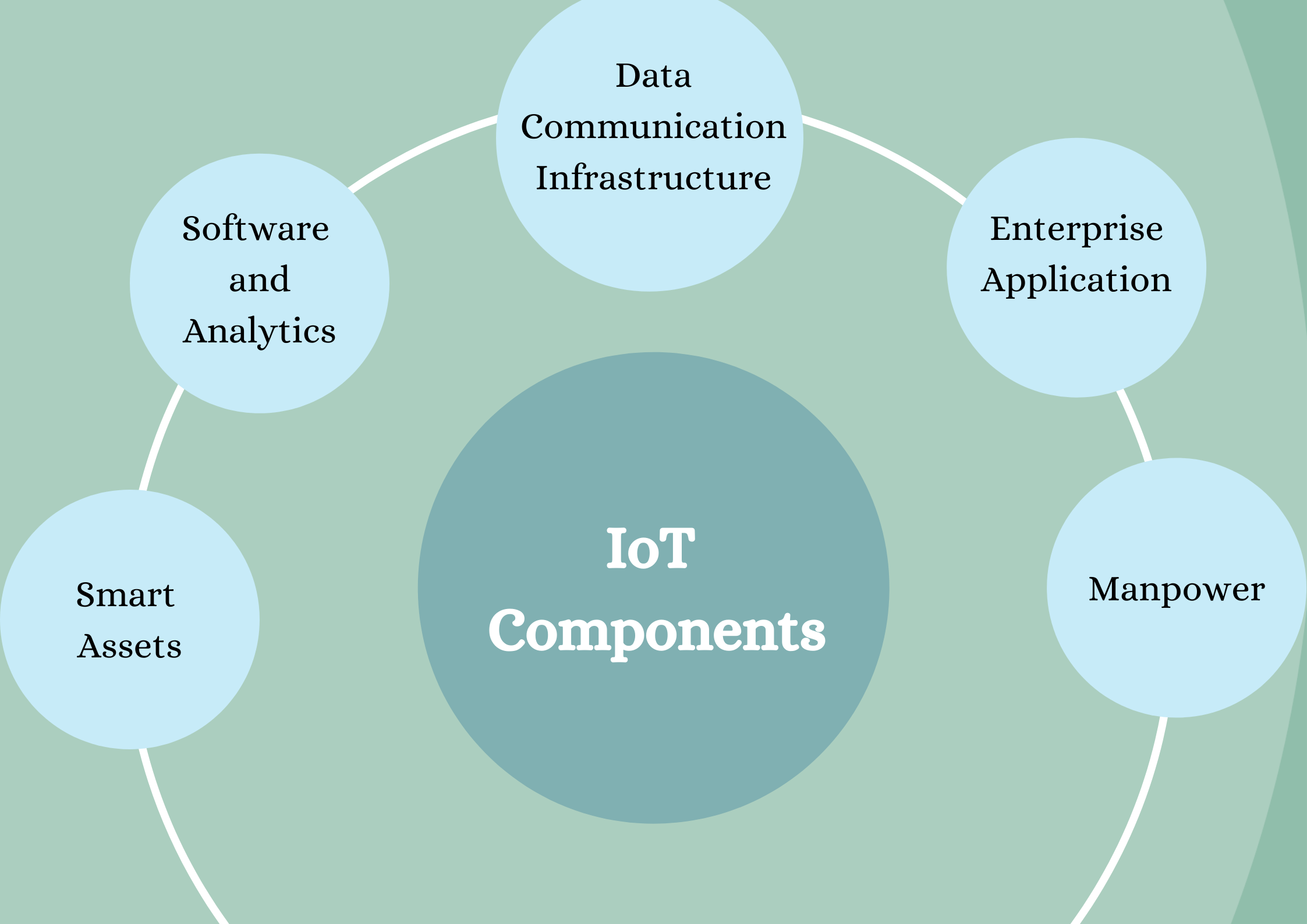

IoT defines the network of physical objects supported by software applications, sensors, and other technologies to exchange data. This data exchange occurs between systems and devices over the internet connection. These devices differ from user to user, from fitness trackers to industrial tools. By 2030, over 100 billion devices are predicted to become IoT-enabled.

IoT has already broken all possible barriers by interconnecting diverse technologies like 5G, Blockchain and Big Data. The statistics revealed by MarketWatch state that the manufacturing industry with the support of IoT integration is expected to grow from USD 12.6 billion (2017) to USD 45.3 billion (2022).

An array of factors drives this IoT market growth. Some of the most significant ones include the need for centralized maintenance, monitoring of manufacturing infrastructure, and adoption of cloud infrastructure. With these promising figures, implementing IoT services in the manufacturing industry is the best way to bring digital transformation.

Business Impact of IoT in the Manufacturing Industry

1. Cost reduction

Due to inventory management, reduced machine downtime, agile operations, and efficient energy use, the company’s operational cost has lowered. For instance, smart, connected products support personalized selling experience, product usage, and post-sale services.

2. Shorter time-to-market

Faster with efficient manufacturing and supply chain operations allows for shortening product development time. Leading automotive brand leveraged IoT to reconfigure its manufacturing unit and manage to reduce the time from 3 days to 6 hours.

3. Mass Customization

The mass customization process needs a significant surge in the variety of produced SKUs, making inventory quite diverse. The manufacturing process becomes more complex too. Inventory management and manufacturing operations becomes challenging and, in some situations, not possible. IoT supports mass customization by providing real-time data needed for thoughtful forecasting, scheduling, and routing.

4. Improved Safety

IoT integrated with Artificial intelligence solutions helps to ensure a safer workplace. Wearable devices assist in monitoring workers’ health states and activities that can lead to possible injuries. In addition to safety, IoT addresses problems experienced in potentially hazardous environments. For example, in the oil and gas industry, IoT analyzes gas leakages as it passes through the lengthy pipe network.

5. Smart Packaging

Smart packaging using materials embedded with IoT provides advanced benefits to manufacturers. The key features of smart packaging are customer engagement and data insights to handle a product effectively. Smart packaging helps to represent product usage through videos, tutorials, and other demonstrations.

IoT aids packaging work in diverse ways, using sensors, QR codes, and augmented reality/virtual reality options. The whole objective is to add value for consumers and collect data via smart tracking. Overall helps to optimize operations and enhance efficiency.

6. Dynamic Response to Market Demands

Meeting market demands depends on multiple factors including taste and preferences, competition, consumer choices, demographics, and so on. Keeping up with demands needs deep research and existing supply could cause big losses to business sales and decisions.

IoT helps to retrieve information continuously without human intervention. It controls supply chains too because the data gathered is accurate to a large extent.

Challenges to IoT Adoption in Manufacturing Industry

According to experts, the core challenges enterprises experience starting IoT-enabled digital transformation include data security, lack of qualified employees, and many more. Here we have mentioned them in detail for proper understanding.

-

Uncertainty about Business ROI

IoT initiatives involve multiple investments categories like spending on hardware (sensors, gateways), cloud storage, admin team, connectivity, and overall support. Businesses have to manage how quickly they can release new solutions in the market and how fast a solution will start generating desired revenue.

2. Data Privacy Issues

58% of manufacturing units believe IoT increases the risk of cyberattacks. Another eye-opening fact is that 20% of IoT adopters have no plan to prevent losses from security threats. As IoT devices become more popular, the possibility of security threats surging in the next few years is very high. Gartner predicts that 30% of attacks are on IoT, while the expenditure on IoT security will reach the $5 billion mark.

-

Lack of Talented Staff

Experts claim that around 70% of businesses lack management-level people with experience in IoT. Furthermore, 60% of ground staff lack skills in IoT deployment. Another prominent research found the skills lacking, including expertise in big data, software development, embedded electronics, IT security, and AI.

-

Integrating Technologies with Legacy Devices

The core challenge of rolling out IoT solutions in legacy ecosystems is to avoid data losses and security issues. Ensuring a streamlined merging of IoT and legacy systems is difficult because, in the past, the system had different objectives. They developed different technology standards and networks. Adopting Ethernet protocols and fast diffusion of web-based user interfaces are easing the integration process, but the challenge is still present.

IoT Solutions for Manufacturing Companies

-

Supply Chain Optimization

IoT is necessary to get products from production to customer on time. IoT applications keep the factory floor stocked with all necessary inventory. In addition, AI integration can look at component quantities, raw material stock, expiration dates, and optimize the distribution channel.

-

Predictive Maintenance

A major challenge for production operation is to keep machinery in good working condition. Now with the power of sensors, and machine learning algorithms manufacturers can analyze data insights to predict possible breakdowns. Maintenance can be scheduled before the predicted machine breakdown.

-

Energy Management

IoT helps the often-overlooked area of energy consumption. With Artificial intelligence solutions, the energy consumption of a production operation can significantly lower overall operations costs. Reduced costs can be utilized for process improvement resources which ultimately yield higher efficiency and product quality.

Wrapping Up

The Industrial IoT helps manufacturing enterprises to maximize productivity through maintaining production uptime, reducing costs, and eliminating waste. Leveraging IoT data, manufacturers get a better understanding of their processes. Besides, supply chain optimization, improved forecasting, shorter time to market, and enhanced customer experience benefit companies markedly. However, considering the scale and the complexity of the Industrial IoT initiatives, successful IoT adoption requires thoughtful orchestration throughout the IoT application design and execution segments.

FAQs

- What are the advantages of IoT technology for businesses?

Here are the advantages of inducing IoT technology in your business-

- Enhanced security protocols

- Reduced Communication cost

- Efficient power consumption

- Better monitoring with increased speed

- Better surveillance tracking

- How do I find a cost-effective full-stack IoT development company?

If you are planning to hire an IoT app development team with a limited budget, then it is suggested to go for an experienced enterprise app development company like OrangeMantra. We are a reputed company with several years of experience in delivering sheer excellence to global clients.

- Do you assure about the security & confidentiality of the app idea?

Yes, we sign a strict NDA to secure your app idea & data. Hence, we ensure the complete security and privacy of your mobile app development project.

- How much time is needed for IoT app development?

The time to create a mobile app is based on several factors ranging from features, scalability, hosting server, and functionality.